Double Sided Transfer Tapes

What Are Double-Sided Transfer Tapes?

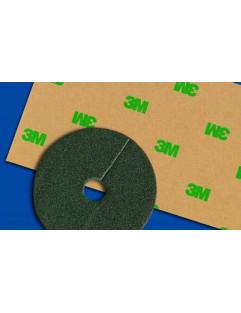

Double-sided transfer tapes consist solely of a layer of pressure-sensitive adhesive (PSA) coated onto a release liner, without a backing material. They are lightweight, flexible, and designed for precise bonding applications. To use, the adhesive is applied to a surface, and the liner is peeled away, leaving behind a clean bond.

Benefits of Double-Sided Transfer Tapes

• Thin and Flexible Design

Their lack of a backing material makes them ideal for applications requiring minimal bulk or an invisible bond line.

• High Precision Bonding

These tapes provide clean and accurate adhesion, making them suitable for intricate applications like graphics and electronics.

• Versatility

They adhere to various materials, including paper, plastics, foam, and metals, and offer options like high tack, temperature resistance, and solvent resistance.

• Ease of Application

Double-sided transfer tapes are easy to apply manually or with applicators, ensuring efficient bonding without mess or residue.

• Lightweight Solution

Their lightweight nature makes them suitable for applications requiring minimal added weight.

Main Applications

• Graphics and Signage

Used for mounting nameplates, emblems, and decorative elements where aesthetics matter due to their seamless finish.

• Electronics Assembly

Ideal for securing components like circuit boards or displays due to their conformability to intricate shapes.

• Medical Devices

Biocompatibility allows safe attachment of components in medical devices.

• Automotive Industry

Bonding trim components, badges, and emblems while resisting vibrations over time.

• Paper and Print Industry

Used for bonding cardstocks and printed materials discreetly without compromising appearance.

• Textile and Fabrics

Provides strong yet invisible bonds in garment manufacturing or fabric assembly.

• Aerospace Applications

Lightweight bonding solutions for critical components where strength and reliability are essential.

• Packaging Industry

Secures packaging materials while maintaining a clean finish during transportation or display assembly.